Alumina capillaries DEGUSSIT AL23

Alumina capillaries or bifilars are used in pyrometry and in particular for the manufacture of thermocouples. Alumina has ideal electrical insulating properties for this type of application. Other properties such as its high temperature resistance (up to 1950 °C), good thermal conductivity or its excellent resistance to wear and corrosion make it a material of choice for high performance applications. We offer capillaries in round and oval shapes, with 2, 4, 6 or 8 holes made of Kyocera DEGUSSIT AL23 alumina.

What is a ceramic capillary?

A capillary is a ceramic tube obtained by extrusion, in the form of multi-channel or bifilar tubes. It is a ceramic tube with several holes or channels. It can have 2, 4, 6 or 8 holes (or even more for some applications). It is ideal for insulating different electrical wires not only from corrosive, high temperature or other external environment but also for electrically insulating these different wires from each other. It allows to replace the use of several tubes by only one, which represents a space saving.

Why choose alumina to manufacture capillaries?

Alumina is a technical ceramic with many thermal, electrical, mechanical and chemical properties. It is an excellent electrical insulator at high temperatures: its electrical conductivity is as low as that of a plastic material. But unlike plastic, it is resistant to high temperatures (up to 1950 °C for 99.7% pure alumina DEGUSSIT AL23). Materials such as zirconia are electrically insulating but only at low temperatures (their electrical conductivity increases with heat) whereas temperature has no influence on the electrical insulation performance of alumina. Aluminum oxide is also a good thermal conductor. This combination of properties makes it the ideal material for thermocouple protection. Indeed, alumina can prevent any current from flowing between the different wires of the temperature sensor and can protect it from a high temperature atmosphere. The thermal conductivity of the material ensures that the measurements will be accurate and fast: the protection does not interfere and does not distort the result.

In addition, aluminum oxide offers very good resistance to wear, corrosion and mechanical abrasion. This ensures a long operational life for our capillaries and other alumina products. It is a chemically inert material with high dimensional stability even at very high temperatures. Finally, alumina is also resistant to thermal shock.

What are the different types of capillaries we sell?

Our standard products include Kyocera DEGUSSIT AL23 round multi-channel alumina capillaries. They can have 2, 4, 6 or 8 holes. Their external diameter varies from 0.9 mm to 8.5 mm. Their maximum length is fixed according to the diameter at 400 mm, 800 mm or 1200 mm, even more in special manufacture.

We also offer oval capillaries. The width of their cut varies between 1.55 mm and 4.2 mm, their height can go from 0.9 mm to 2.2 mm and their maximum length is fixed at 400 mm, even more in special manufacture.

You will find these two products in the catalog of standard products

We also offer capillaries with standard dimensions for thermocouples. They are made of DEGUSSIT AL23, their external diameter varies from 4 mm to 8.5 mm and their maximum length is fixed at 2060 mm.

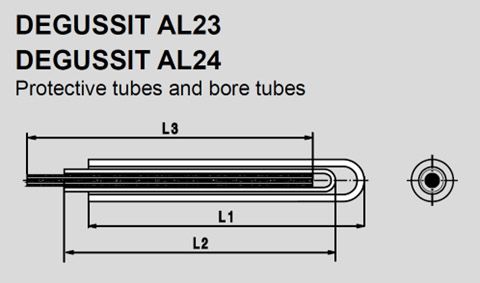

You can find these standard capillaries in the catalog and refer to this table to determine the suitable dimensions of the sheaths and capillaries for the protection of a thermocouple.

| Length of the outer protection tube (L1) | Length of the inner protection tube (L2) | Length of the capillary (L3) |

| 180 | 200 | 205 |

| 250 | 270 | 275 |

| 350 | 370 | 375 |

| 500 | 530 | 560 |

| 710 | 740 | 770 |

| 1000 | 1030 | 160 |

| 1400 | 1430 | 1460 |

| 2000 | 2030 | 2060 |

For which applications can a capillary be used?

Ceramic capillaries can be used to insulate wires and cables, for high temperature applications in the glass industry and industrial ovens for example. They are particularly used in pyrometry for the protection of temperature measuring devices. They are used in particular for the protection and the insulation of the temperature rods.

Thermocouples are made of two wires (platinum and platinum-rhodium) and measure the temperature by the Seebeck effect. Sheaths are used to electrically insulate the soldering of the two thermocouple wires from the outside and also to protect the temperature sensor from a corrosive or abrasive environment. The capillary is used to insulate the two wires from each other over their entire length.