Ceramic materials

The ceramic materials we offer are used for their thermal, electrical and mechanical properties which enable them to be used for high performance and therefore very demanding applications. Our ceramic materials include alumina, zirconia, mullite, silicon carbide, silicon nitride and MACOR®. They are used for example in the aerospace, medical, electronics, petrochemical, luxury, defence and aerospace industries. Each material is available in a range of purity, porosity, etc., which makes it possible to adapt to these sectors of activity.

What are the different ceramic materials we offer?

We offer alumina products. Depending on the product, different types of alumina are available. You will find 99.7% pure alumina such as Kyocera DEGUSSIT AL23, F99.7 or F99.7hf. We also offer DEGUSSIT AL24 alumina, which is slightly porous and particularly resistant to creep (over 99.5% pure), DEGUSSIT AL25 porous alumina, which is the most resistant to thermal shock, or FZT (ZTA) alumina, which is reinforced with zirconia grains. Finally, in our range of superfinishing tools you will find chromium oxide doped alumina (ruby alumina): DEGUSSIT DD57.

For Kyocera zirconia products, we offer zirconia partially stabilised with yttrium oxide (3Y-TZP, DEGUSSIT FZY), magnesium oxide or magnesia (FZM (Mg-PSZ) or DEGUSSIT ZR25). We also have fully stabilised zirconia (with yttrium oxide) in cubic form: 8Y-FSZ, for very high temperatures.

We also offer products made of Kyocera's dense sintered silicon carbide (SSiC) or porous (recrystallised) SiC-R. Similarly, our mullite products can be either dense mullite (C610) or porous mullite (C530).

Finally, we also have product ranges in StarCeram® N 7000, 3000 and 8000 silicon nitride (Si3N4) and MACOR® machinable glass ceramics.

How are ceramic parts made?

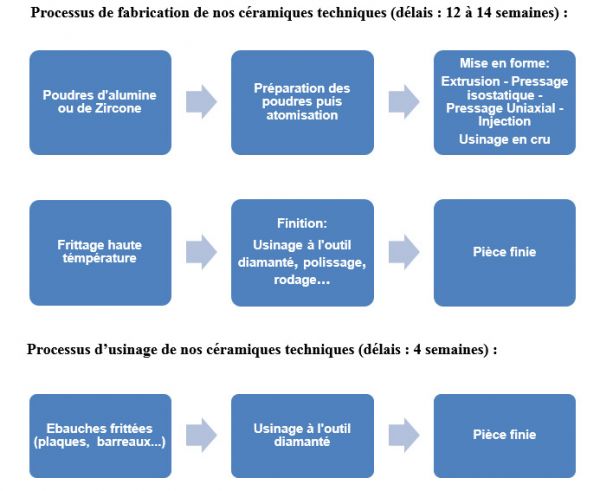

Ceramic parts, whether alumina or zirconia, have identical manufacturing processes.

- The manufacturing process starts with the selection of a high quality and pure alumina or zirconia powder, which is the most important phase for the final quality of the ceramic. We use a powder of controlled particle size and superior quality, which is atomised. This atomisation stage guarantees homogeneous products and a high quality industrial ceramic.

- The second step concerns the shaping of the raw material. Depending on the requirements, we use different processes.

- Uniaxial pressing consists of placing the material in a suitable pressing die and exerting a pressure of several hundred bars on one side (axis) of the material. This makes it possible to obtain simple shapes such as plates or discs.

- Isostatic pressing consists of putting the powder in an elastic container (such as a rubber) and this time exerting hydrostatic pressure on all sides at the same time. This pressure of 1800 to 2000 bar is exerted via a liquid. This usually results in parallelepipedic blocks which are then cut and machined by numerical control: this is raw machining.

- Extrusion is used to produce tubes, rods, sheaths, capillaries, etc., from suitable dies. The material is pushed through a suitable die with an endless screw.

- Injection moulding, also known as CIM for Ceramic Injection Molding, consists of mixing ceramic powder with a plastic material, then injecting it into a mould. The plastic material is removed during the debinding phase.

3. Next comes the high-temperature sintering stage. This heat treatment stage is the one that will enable the desired final product to be obtained, with its final properties and dimensions. This stage consists of heating the material in a furnace at a temperature above 1700°C, but below the melting temperature, for several dozen hours. During this time, its microstructure will evolve: the ceramic grains will weld together by solid diffusion; the material will become denser. The porosity will be reduced to zero. The part will therefore decrease in size by up to 50% in volume depending on the ceramics used.

4.The last stage is the grinding and finishing stage. Indeed, the size reduction during sintering is controlled, and the moulds are manufactured taking this into account, but it is sometimes necessary to do a final finishing or polishing to achieve the precision and surface finish required by our customers on technical ceramic products.

All of these steps from start to finish take 12-14 weeks.

What are the properties of our materials?

Our ceramic materials offer a variety of characteristics: for example, remarkable thermal, mechanical or electrical properties that make them high-performance ceramics.

Most of the materials can withstand very high temperatures, above 1000 °C (up to 1950 °C for alumina, for example). Others, such as silicon carbide, are used for their very high thermal shock resistance. These technical ceramics generally offer very good dimensional stability, even at high temperatures. In addition, these ceramics are chemically inert. Zirconia in particular does not react at all with the products with which it is brought into contact.

Our ceramic materials are also particularly resistant to wear and corrosion. Silicon carbide withstands mechanical abrasion very well, which makes it possible to produce parts with a long service life. Some are very good thermal insulators (such as MACOR®) while others such as alumina and silicon carbide are thermal conductors. This makes it possible to find materials that are suitable for making rapid temperature measurements or, on the contrary, for effectively isolating two media with a large temperature difference.

Ceramics are also excellent electrical insulators. In particular, the electrical conduction of aluminium oxide is as low as that of plastic materials. This makes it an ideal electrical insulator for high temperature applications. Finally, an important property of the materials is their machinability. MACOR® in particular is a very machinable glass-ceramic: it is an ideal material for machining parts with complex geometries with conventional tools.

In what applications can ceramic materials be used?

Our ceramic materials, thanks to their properties, can be used in high performance applications. They are used in the aerospace, luxury goods, medical, defence, food, pharmaceutical, chemical, automotive, plastics and metallurgical industries. They are also often used in electronics for their semiconductor properties.

In the luxury sector, zirconia is particularly appreciated for its machinability, chemical inertia and resistance to wear. Ceramics and glass ceramics are generally used in jewellery and watches.

In the defence industry, ceramic materials are known for their hardness, lightness, mechanical strength and electrical insulating properties. They are used in particular to make light ballistic protection.

In aeronautics and aerospace, ceramic materials are used because they are much more suitable than metals and plastics. They make excellent electrical insulators, even at high temperatures and pressures. Industrial ceramics are wear-resistant and chemically inert. This makes them ideally suited for the manufacture of parts such as pyrotechnic initiators, gyroscopes, accelerometers, or spark plugs.