The MACOR® material and its uses

MACOR® is a glass-ceramic material. Its many properties make it a material of choice for many fields of application, whether in industry, research ... One of its main assets is its outstanding machinability, which allows it to take on very complex shapes and geometries. In addition to this soft metal-like machinability, MACOR® offers the advantages of a technical ceramic and the versatility of a high performance polymer.

The properties of MACOR®

MACOR® can be an effective alternative to Kyocera DEGUSSIT alumina technical ceramics when conditions are less demanding, e.g. with regard to high temperatures and/or mechanical strength. MACOR® has a unique combination of properties. This odourless, white material has a coefficient of expansion similar to most metals and sealing glasses. It has zero porosity. It is stable up to 800 °C (continuous) and even 1000 °C (peak). Even at such high temperatures, unlike ductile materials, it does not deform. It also benefits from this dimensional and microstructural stability against radiation.

MACOR® is an excellent electrical insulator, even at very high temperatures. Its electrical conductivity is very low, similar to that of a plastic material for example. These insulating properties make it an excellent choice for high voltage applications.

One of the most important features of this material is its machinability. Indeed, thanks to its composition (55% fluorophlogopite (Mica) & 45% borosilicate glass), it has an excellent resistance to machining, even very tightly. Its remarkable machinability allows dimensions of +/- 0.013 mm, a polish of 0.013 μm and surface finishes of less than 0.5 μm.

MACOR® presentation: Machinable glass-ceramic brochure

| Material | MACOR® |

| Microstructure | |

| Composition (by weight) | 55% mica + 45% borosilicate |

| Density | 2,52 |

| open porosity (%) | 0 |

| Mechanical properties | |

| Compressive strength (MPa) | 345 |

| Module of elasticity (GPa) | 66,9 |

| Thermal Properties | |

| maximum operating temperature (°C) | 1000 |

| specific heat (J/Kg.K) | 790 |

| Thermal conductivity 100 °C (W/m.K) | 1,46 |

| Coefficient of expansion (10-6/K) | 12,3 |

| Electrical properties | |

| Resistance at 20 °C (ohm.cm) | 1017 |

| Electrical rigidity (kVeff/mm) | 45 |

MACOR®, a ceramic that can be easily machined

Machining refers to the steps necessary in the manufacturing process to go from a raw material to finished parts made of this material. In order to ensure good machining, care must be taken in the choice of cutting speed and the cooling fluid used. Machining MACOR® is known for its simplicity as it uses standard tools. Indeed, although carbide tools provide better results, it is possible to machine MACOR® with steel tools. A water-soluble cutting oil (suitable for machining glass and ceramics) is ideal.

For grinding, diamond wheels made of alumina or silicon carbide are ideal. As far as polishing is concerned, the most effective way to achieve a polish of 0.013 μm is to start the process with a steel wheel and P400 silicon abrasive powder and finish it with a felt wheel and alumina abrasive powder. For good sawing, a carbide-tipped blade with a speed of about 0.5 m/s should be used. Alternatively, silicon carbide or diamond cut-off wheels can be used. Finally, it is advisable to tap in one direction only, with constant watering to avoid machining sludge and scuffing.

Machining MACOR® has many advantages. Despite the simplicity of the tools used, it is possible to obtain parts with very complex geometries. In addition, no annealing or heat treatment is required after machining, which reduces the production time of the parts. This reduction in production time and the possibility of using conventional tools ensures the material's profitability.

Fields of application of MACOR® ceramic material

The machinable ceramic material MACOR® is used in a wide range of fields. It is used in the chemical, automotive, weapons, laser technology and other sectors. Its properties are useful in the aerospace and aviation industries (e.g. its sealing properties are ideal for making seals on certain probes or retaining rings). It is often used in ultra-high vacuum or constant vacuum environments (as an insulator or coil carrier). It is also used in the medical field as it is an inert material. It is regularly used in the nuclear industry as it is resistant to radiation. Its excellent strength and dimensional stability against nuclear radiation means that it can easily be used as a dimensional reference in this field. Its resistance to high temperatures also allows it to be used in furnaces for heat treatment.

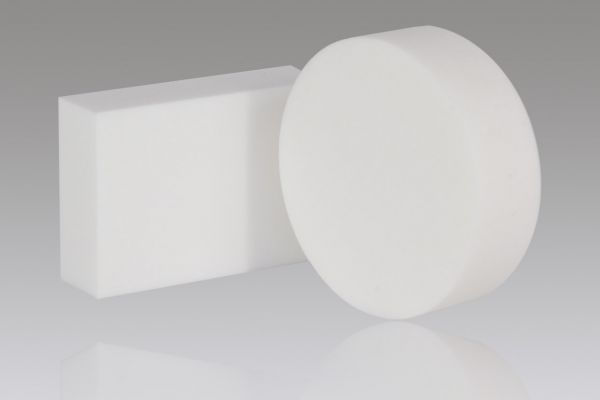

Products made of MACOR®

Umicore is a MACOR® distributor. Semi-finished products are offered to enable our customers to benefit from the exceptional machinability of this material. We offer raw plates with dimensions of 317 x 317 x 54 mm), rods (76 mm diameter, 311 mm length), strips, rods... However, customers also have the possibility to ask for parts with much more complex geometries (with almost infinite possibilities thanks to the properties of MACOR®). In these cases, the machining to plan and the finishing of the parts will be carried out by a partner company specialising in this sector.