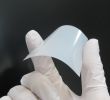

Thin Technical Ceramic Substrates

Thin alumina or zirconia substrates

Thin ceramic substrates

Thin ceramic substrates made of alumina or zirconia

Thin ceramic substrates are manufactured by tape casting, which produces thin but large ceramic sheets. This process consists of coating a powder suspension on a flat surface with solvents, dispersing agents, binders and plasticizers.

KERAFOL® is the reference company in the manufacture of thin ceramic substrates in Europe. These alumina or zirconia substrates can be used in many applications: furnace construction, medical technology, electronic sensors, catalysts, SOFC fuel cells, liquid filtration...

Main characteristics of thin ceramic substrates

- High temperature resistance

- Very good resistance to corrosion, mechanical abrasion and wear

- Relatively light

- Extreme hardness

- Low heat capacity

- High mechanical strength

- High flexibility of thin substrates

High temperature thin substrates:

KERAFOL® has long experience in the development and production of thin ceramic substrates. They are made of alumina and are used in high temperature applications.

We offer different thin ceramic substrates according to your needs:

- Keral 99 composed of more than 99.6% alumina

- Keral 96 composed of 96% alumina

- Keralpor 99 made of 99.5% porous alumina

- Keralpor S composed of alumina and a zirconia deposit

Thin substrates for liquid filtration:

KERAFOL® produces porous alumina discs and plates of varying dimensions for micro and ultra filtration of liquids. The combination of technical ceramics and the dynamic cross-flow filtration system allows efficient filtration of flows with low energy consumption.

Applications of thin porous alumina substrates:

- Chemical industry

- Water treatment

- Liquid filtration (wine, fruit juice, etc.)

- Oil and gas industry

- Pharmaceutical and biotechnology industry

Thin substrates for SOFC/SOEC fuel cells:

Since 1990, KERAFOL® has been involved in SOFC/SOEC fuel cell technology. In addition to producing substrates for electrolyte cells, KERAFOL® also manufactures glass sheets for the hermetic sealing of fuel cells.

Features of SOFC fuel cells :

- Environmentally friendly technology

- Efficient conversion of chemical energy into electrical energy

- Ideal solution for decentralised energy supply

- Can be used in micro CHP applications (simultaneous production of heat and mechanical energy)

Thin firing porcelain substrates:

KERAFOL® manufactures porcelain firing sheets for decorative and design applications. Before firing, these thin substrates have the advantage of being malleable and can be easily worked by the artist's hand. The KERAFLEX® product range opens up new possibilities in the processing of porcelain in artistic and technical applications.

Please see our product range for more information or contact us for your custom orders for specific applications